Application

- LPm booster pump is suitable for boosting hot water powered by solar energy for sauna

and bathing. It solves the problem of insufficient water pressure in high-rise

buildings.

- It can also supply water (less than 100℃) to two family homes.

LPm Booster Pump Features

- Cast iron pump body and support under special anti-rust treatment

- AISI 304 shaft

- Liquid temperature: 2 - 100℃

LPm Booster Pump Motor Features

- Insulation class:F

- AISI 304 shaft

- Protection class: IP 44

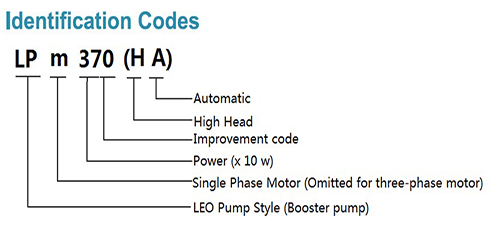

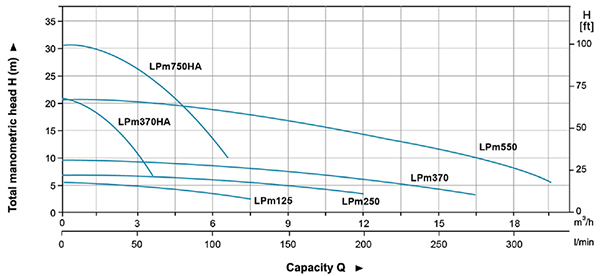

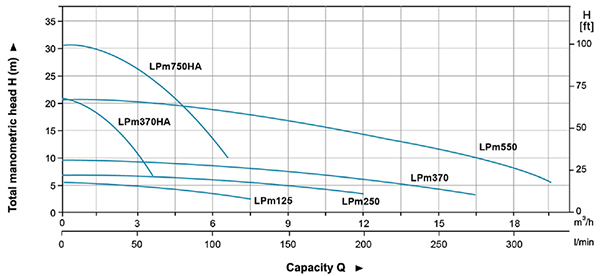

LPm370HA、LPm750HA Booster Pump of Hydraulic Performance Curves

Technical Data of LPm Booster Pump

| MODEL |

POWER (kW) |

| LPm125 |

0.125 |

| LPm250 |

0.25 |

| LPm370 |

0.37 |

| LPm550 |

0.55 |

| MODEL |

POWER (kW) |

| LPm370HA |

0.37 |

| LPm750HA |

0.75 |

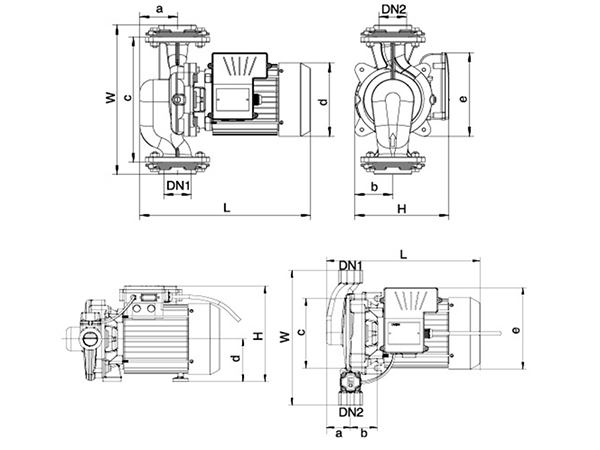

| MODEL |

DN1 |

DN2 |

L (mm) |

W (mm) |

H (mm) |

a (mm) |

b (mm) |

c (mm) |

d (mm) |

e (mm) |

| LPm125 |

1 1/2" |

1 1/2" |

275 |

260 |

186 |

47 |

74 |

210 |

∅ 141 |

160 |

| LPm250 |

2" |

2" |

301 |

313 |

190 |

71 |

78 |

260 |

∅ 141 |

164 |

| LPm370 |

2 1/2" |

2 1/2" |

367 |

334 |

195 |

77 |

84 |

280 |

∅ 141 |

173 |

| LPm550 |

2" |

2" |

369 |

344 |

210 |

81 |

87 |

280 |

∅ 165 |

182 |

| LPm370HA |

1" |

1" |

295 |

270 |

209 |

43 |

60 |

124 |

∅ 95 |

141 |

| LPm750HA |

1" |

1" |

341 |

310 |

220 |

54 |

59 |

160 |

∅ 98 |

166 |

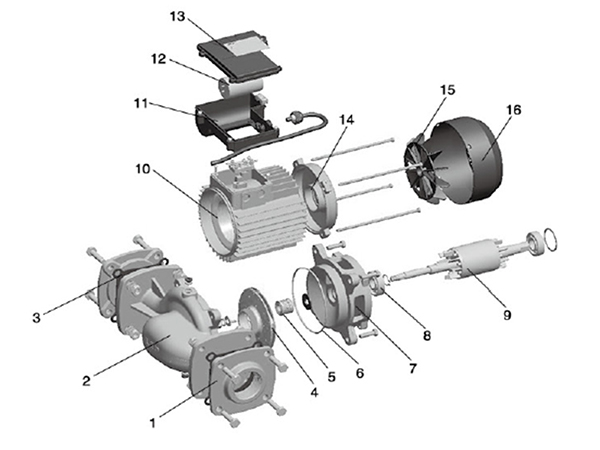

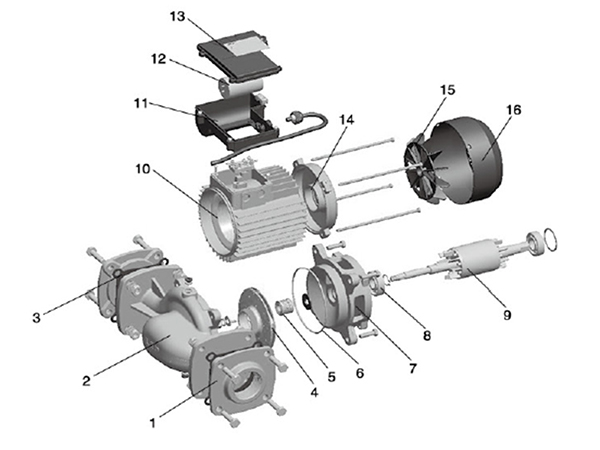

Material Table(LPm125、LPm250、LPm370、LPm550)

| No |

Part |

Material |

| 1 |

Flange |

HT200 |

| 2 |

Pump body |

HT200 |

| 3 |

Flange gasket |

|

| 4 |

Impeller |

PPO |

| 5 |

Mechanical Seal |

Carbon/Ceramic |

| 6 |

O-ring |

|

| 7 |

Support |

HT200 |

| 8 |

Bearing |

|

| 9 |

Rotor |

|

| 10 |

Stator |

|

| 11 |

Terminal Box |

ABS |

| 12 |

Capacitor |

|

| 13 |

Terminal Box cover |

|

| 14 |

Rear Cover |

ZL 102 |

| 15 |

Fan |

PP |

| 16 |

Fan cover |

08F |

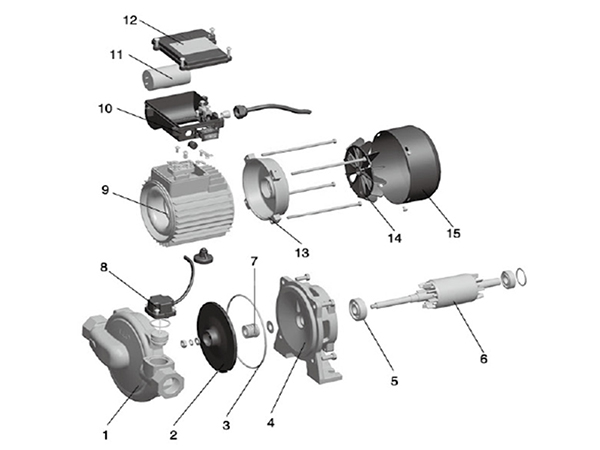

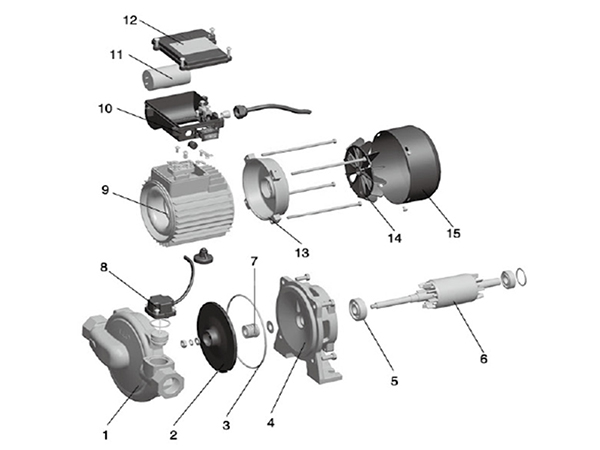

Material Table (LPm370HA、LPm750HA)

| No |

Part |

Material |

| 1 |

Pump body |

HT200 |

| 2 |

Impeller |

PPO |

| 3 |

O-ring |

|

| 4 |

Support |

HT200 |

| 5 |

Bearing |

|

| 6 |

Rotor |

|

| 7 |

Mechanical seal |

Carbon/Ceramic |

| 8 |

Control switch |

|

| 9 |

Stator |

|

| 10 |

Terminal Box |

ABS |

| 11 |

Capacitor |

ABS |

| 12 |

Terminal Box Cover |

|

| 13 |

Rear Cover |

ZL 102 |

| 14 |

Fan |

pp |

| 15 |

Fan cover |

08 F |